To adjust the air compressor pressure switch, locate the adjustment nut and turn it clockwise to increase pressure or counterclockwise to decrease pressure. If you need to adjust the pressure settings of your air compressor, the process is relatively simple.

By finding the adjustment nut, you can easily increase or decrease the pressure according to your needs. This step-by-step guide will walk you through the process and ensure that you can adjust the pressure switch accurately. Whether you want to increase the pressure for high-powered applications or decrease it for more delicate tasks, this guide will provide you with the necessary information to make the necessary adjustments.

So, let’s jump in and learn how to adjust the air compressor pressure switch.

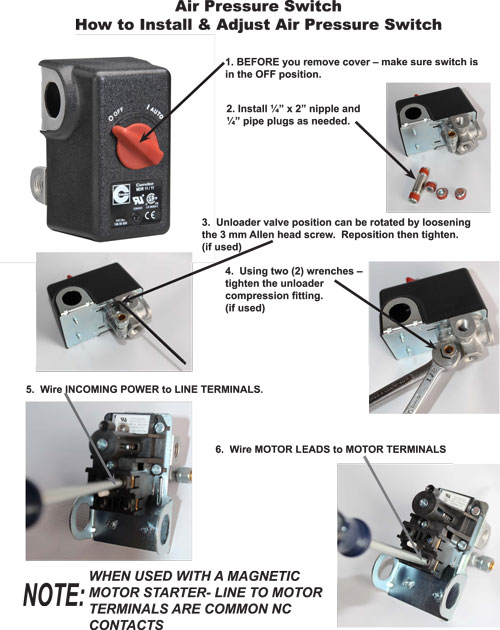

Credit: www.industrialaircompressors.biz

Understanding The Air Compressor Pressure Switch

The air compressor pressure switch plays a crucial role in controlling the pressure levels of your air compressor. Understanding how this component works and being able to adjust it accordingly is essential for optimal performance. In this section, we will delve into the details of the air compressor pressure switch, including what it is, how it works, and why it is important to fine-tune it.

What Is The Air Compressor Pressure Switch?

The air compressor pressure switch is a device that automatically turns the air compressor on and off based on the preset pressure levels. It is typically located near the compressor tank and is responsible for monitoring and maintaining the desired pressure in the tank. This switch ensures that the compressor only runs when there is a demand for compressed air and stops when the pressure reaches the specified upper or lower limit.

How Does The Pressure Switch Work?

The pressure switch is comprised of several components that work together to regulate the air compressor pressure. The primary components include a diaphragm, contacts, springs, and adjustment screws. When the pressure in the tank drops below the predetermined lower limit, the diaphragm senses the change and activates the contacts, which then send an electrical signal to the compressor motor, turning it on. The compressor then fills the tank until the pressure reaches the upper limit, at which point the contacts deactivate and shut off the compressor motor.

Why Is It Important To Fine-tune The Pressure Switch?

Fine-tuning the pressure switch is crucial for several reasons. First, it ensures that the air compressor maintains the correct pressure levels, preventing potential damage to both the compressor and the connected equipment. Second, adjusting the pressure switch allows you to optimize the compressor’s performance, helping it operate efficiently and reducing energy consumption. Lastly, fine-tuning the pressure switch can extend the lifespan of your compressor by preventing excessive wear and tear caused by inconsistent pressure levels. It is essential to regularly check and adjust the pressure switch to ensure safe and optimal operation of your air compressor.

Identifying The Need For Fine-tuning

When it comes to operating an air compressor, ensuring that the pressure switch is properly adjusted is crucial. The pressure switch serves as a control mechanism for regulating the pressure within the compressor tank. However, over time, these pressure settings may need some fine-tuning to maintain optimal performance. By identifying the signs of a poorly adjusted pressure switch, understanding the importance of maintaining optimal pressure, and considering the safety concerns associated with improper settings, you can take the necessary steps to adjust your air compressor pressure switch for better efficiency.

Signs Of A Poorly Adjusted Pressure Switch

If your air compressor is exhibiting any of the following signs, it may indicate that the pressure switch needs adjustment:

- Irregular or inconsistent pressure output

- Frequent cycling or short cycling

- Inability to reach the desired pressure

- Noisy or abrupt cut-off

- Excessive heat generation

These signs suggest that the pressure switch is not functioning optimally and may require fine-tuning to maintain proper pressure levels.

Importance Of Maintaining Optimal Pressure

Optimal pressure is crucial for the efficient operation of an air compressor. Maintaining the correct pressure level ensures that the compressor can deliver adequate air flow to power tools and equipment. It also maximizes the lifespan of the compressor by preventing unnecessary wear and tear.

Additionally, preserving optimal pressure helps to minimize energy consumption, enhancing the overall efficiency and cost-effectiveness of the compressor. By regularly adjusting and monitoring the pressure switch, you can maintain the desired pressure and keep your air compressor performing at its peak.

Safety Concerns With Improper Pressure Settings

Improper pressure settings not only impact the performance and efficiency of an air compressor but also raise safety concerns. Pressure that is too high can lead to equipment failure, leaks, and even ruptures, posing a risk to both the operator and nearby individuals. On the other hand, insufficient pressure can result in reduced tool performance, compromising the safety of specific applications.

By ensuring that the pressure switch is properly adjusted, you can mitigate these safety risks and create a safe working environment for yourself and others.

CODE EXAMPLE

// Example code for adjusting the pressure switch

function adjustPressureSwitch()

{

// Check manufacturer's guidelines for the specific air compressor model

const optimalPressure = 90;

let currentPressure = getCurrentPressure();

// Compare current pressure with optimal pressure

if (currentPressure > optimalPressure)

{

decreasePressure();

}

else if (currentPressure < optimalPressure)

{

increasePressure();

}

else {

return; // Pressure is already optimal

}

adjustPressureSwitch(); // Repeat adjustment until optimal pressure is reached

}

Steps To Fine-tune Your Air Compressor Pressure Switch

Learn how to fine-tune your air compressor pressure switch with these easy steps. Adjusting the pressure switch can ensure efficient operation and prevent damage to your air compressor.

Preparation And Safety Precautions

Before you start adjusting your air compressor pressure switch, it is essential to take certain preparation steps and ensure your safety. Follow these precautions to prevent any accidents or damage:- Disconnect the power supply to the air compressor to avoid any unexpected startups.

- Release any remaining pressure from the air compressor by activating the pressure release valve.

- Wear appropriate safety gear, including safety goggles and gloves, to protect yourself from potential hazards.

- Ensure you have a clear workspace with adequate lighting to work comfortably and safely.

Accessing The Pressure Switch

To adjust the pressure switch, you need to locate and access it on your air compressor. Follow these steps:- Refer to your air compressor manual to identify the location of the pressure switch.

- Switch off the air compressor and disconnect it from the power source.

- Remove any covers or panels that may be obstructing access to the pressure switch.

- If necessary, use a multimeter to ensure the power is completely disconnected before proceeding.

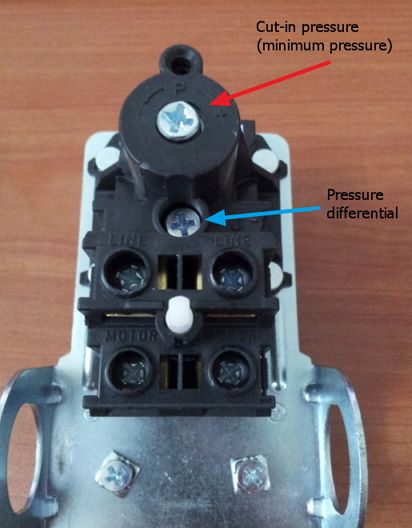

Adjusting The Cut-in And Cut-out Pressures

Now that you have accessed the pressure switch, you can proceed with adjusting the cut-in and cut-out pressures. Follow these steps:- Identify the adjustment screws responsible for setting the cut-in and cut-out pressures. These screws are usually labeled on the pressure switch.

- Using a suitable screwdriver, turn the cut-in screw clockwise to increase the cut-in pressure or counterclockwise to decrease it. Adjust it to your desired value.

- Similarly, adjust the cut-out pressure by turning the cut-out screw. Clockwise increases the pressure, while counterclockwise decreases it. Set it to your desired value as well.

- Make small adjustments and test the results before making any further changes for better precision.

Testing And Validating The New Pressure Settings

To ensure the adjustments you made to the pressure switch are accurate and functioning as intended, follow these steps to validate the new pressure settings:- Reconnect the power supply to the air compressor.

- Allow the air compressor to reach its cut-in pressure and observe if it triggers the pressure switch properly.

- Monitor the cut-out pressure and ensure the air compressor shuts off when it reaches the desired pressure.

- If necessary, make further adjustments to achieve the desired cut-in and cut-out pressures.

- Repeat the testing process until the air compressor operates within the desired pressure range consistently.

Credit: www.aavsales.com

Credit: www.air-compressor-guide.com

Frequently Asked Questions Of How To Adjust Air Compressor Pressure Switch

How Do You Adjust An Air Compressor Pressure Switch?

To adjust an air compressor pressure switch, start by turning off the compressor and relieving the pressure inside the tank. Then, locate the pressure adjustment screws on the switch and use a screwdriver to turn them clockwise to increase the pressure or counterclockwise to decrease it.

Check the pressure gauge to ensure it matches your desired setting.

Why Is It Important To Adjust The Air Compressor Pressure Switch?

Adjusting the air compressor pressure switch is important to ensure optimal performance and prevent damage to the compressor. If the pressure is set too low, the compressor may not deliver enough air for your tools. Conversely, if the pressure is set too high, it can strain the compressor and lead to premature wear or failure.

Proper adjustment helps maintain efficiency and prolong the lifespan of the compressor.

What Are The Signs That The Air Compressor Pressure Switch Needs Adjustment?

If the air compressor cycles on and off too frequently, struggles to reach the desired pressure, or produces inadequate airflow, it may indicate that the pressure switch needs adjustment. Additionally, if you notice a significant difference between the set pressure and the actual pressure displayed on the gauge, it’s a good indication that adjustment is necessary.

How Often Should The Air Compressor Pressure Switch Be Adjusted?

The frequency of adjusting the air compressor pressure switch depends on various factors such as usage, environmental conditions, and the specific compressor model. However, it is generally recommended to check and adjust the pressure switch every few months or whenever there are noticeable performance issues.

Regular maintenance and monitoring of the switch will ensure optimal operation and prevent potential problems.

Conclusion

Adjusting the air compressor pressure switch is a crucial task for maintaining the optimal performance of your equipment. By carefully following the steps outlined in this blog post, you can ensure that your air compressor operates at the desired pressure levels.

Remember to regularly monitor the pressure and make necessary adjustments. By doing so, you can prolong the lifespan of your air compressor and prevent potential issues. Happy adjusting!